Dry contact — this is a contact that does not have an electrical connection to the control device, power and “ground”.

If there are no external circuits connected to the contacts, then there is no voltage or “ground” on them in any state. Therefore, another name “potential-free contact” is found in the literature.

In other words, a dry contact by itself does not supply electric current to electrical appliances, it can only connect or break the electric circuit that you connect to it.

Dry contact — it is primarily a type of switching device. It either connects or disconnects your electrical circuit into which you have connected it. At first, there is no potential on it, no current is applied, its contacts are not grounded. The only important parameters of a dry contact should be the maximum current that can pass through it, and information about the state of its contacts, how they work. Usually there are normally closed, normally open or combined type — switching contacts)).

Simplicity of implementation

It is not difficult to change the connections in the electrical panel so that the required group of equipment works and is controlled through a dry contact.

Economic benefit

The absence of the need to purchase and install additional panel modular equipment allows for significant savings in connection.

Automatic recovery

Every change in the position of the dry contact will be immediately displayed on the equipment that is connected through it. When breaking — it will be disconnected from the power, and when the power is restored, it will automatically appear.

Works with a normally closed contact

For correct operation in responsible systems, for example, in an emergency or evacuation notification, only a normally closed contact is used.

This is done for the possibility of simple control of system performance. Yes, if there is a break in the line going to the dry contact, the equipment will be automatically disconnected, which will help to start looking for the malfunction in time and fix it.

If a normally open contact was used, which would connect in the event of an accident, we would not have known about the line break until the scheduled system testing or until the moment of the accident itself.

Conclusions

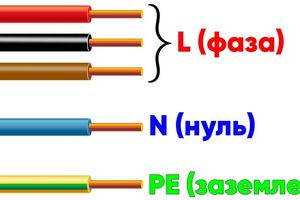

Dry contacts are convenient in that they can be connected to almost any circuit, the type of current and voltage (within the switching capacity of the relay) are not important here, they are galvanically isolated from the control circuit. But this does not mean that they are better or worse than the same contacts with the potential.

For example, in simple systems such as motion or lighting sensors for light control or direct-on voltage relays, dry contacts are often unnecessary, as they are likely to be connected to the same supply line as the device itself. Therefore, the same motion sensors are usually three-wire.

But if you need to make complex automation, for example, using some PLCs, then you will need dry contacts. And if the circuit includes devices with potential contact output, then intermediate relays will have to be added to connect them to the controller.

Attention:

If you need to connect LIVOLO dry contact switches to another manufacturer's relay, or you need devices, you can purchase a LIVOLO sample and check whether it works with your relay.

There are no relays in the assortment of the LIVOLO factory.

About the relay:

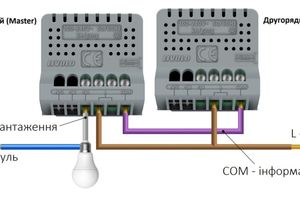

A relay switching device (most often it is an electromechanical relay) for controlling internal equipment.

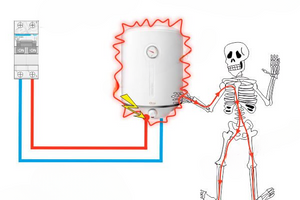

Using a relay, it is possible to organize control of a wide range of equipment: drives of rolling or unfolding gates, barriers, light and sound warning systems, electromagnetic or electromechanical locks. It is possible to use the relay in thermostat mode to control boiler equipment, with connection to the input of an external room thermostat. Implemented pulse control mode with pulse duration setting. The light indicator provides visual control of relay operation modes.